In today’s globalized world, logistics companies play a pivotal role in facilitating the movement of goods and services from producers to consumers. These companies form the backbone of supply chain management, orchestrating intricate processes to ensure products reach their intended destinations efficiently and reliably. Operating in a complex landscape, logistics companies employ a range of strategies to streamline operations and enhance customer satisfaction.

For Energy, optimizing the movement of hydrocarbons can be a complex and intricate challenge requiring innovative solutions. Activera Consulting, in conjunction with our ecosystem partner e2log, took a deeper look at what we’re seeing in the industry and have highlighted two major problems + solutions below.

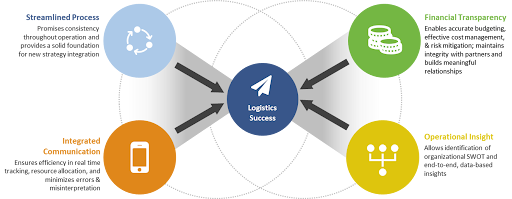

Before we dive into the Energy industry specifics, though, let’s set the stage by looking at a few key principles that make efficient logistics happen:

Now that we’ve outlined four key tenants of logistics excellence, let’s take a look at two problems that rear their ugly heads, specifically in the Energy industry.

Problem 1: Integration Inefficiency

Efficiently transporting energy resources is often hindered by operational inefficiencies that can stem from myriad sources – for example, outdated technological infrastructure, or perhaps missing/dilapidated transportation infrastructure that results in delays and operational complications. At the core of this is a consistent challenge in matching the needs of the shipper with the performance and execution of their logistics partners. Their processes and systems just don’t match up.

Rising fuel and fleet management costs make it even more challenging to maintain profitability – we’ve all seen the significant hike in shipping prices over the past two years. The interplay of these elements adds complexity to an already intricate operational landscape, forcing companies to innovate and adopt strategies that mitigate disruptions while keeping costs manageable.

Solution 1: A Holistic Approach

Amid these challenges emerges a transformative approach that centers on cohesive data integration; one, connected system where different parts of the energy value chain can unite is a step in the right direction. For example, a digital control tower system can enable a 360-degree view of Oil and Gas operations. Using a route optimization tool for workovers or complete views of all inventory at rest and in transit or identifying preventive maintenance opportunities for longevity of systems can help head-off inefficiencies as well. Bottom line, looking end-to-end for proper Systems Thinking use-cases is much better than optimizing component parts, thereby inadvertently creating bottlenecks (see Goldratt’s The Goal).

Problem 2: Lack of Communication

Usually, a handover of some sort happens when moving across Segments from Upstream to Midstream. Production data sits in one system and transportation (Shipping, Trading, Pipeline, Rail, etc.) will sit in another (or in multiple others!). Inadequate communication can further propagate when changes or updates are made along the way. If these changes aren’t promptly communicated at every step of the supply chain, the result can be a process that’s disjointed.

Solution 2: A Facilitation Platform

The ideal solution would provide a clear and structured way to manage and navigate the movement of resources. This approach would track the trajectory of a product from Production (exit point of Upstream) to final destination (exit point of Midstream).

Visualizing the voyage of hydrocarbons can be a powerful advantage. This mechanism empowers stakeholders with real-time insights into the geographical journey of resources, facilitating informed decisions. The overarching goals of a platform in this space are to unify communications for maximum profitability, assist with control over the logistics providers’ performance, and solve deeper issues with data-driven insights.

Navigating the Path of Progress:

As Integrated Oil Companies look towards effective Value Chain (Up, Mid, & Downstream) analysis as a cost-cutting and value generation mechanism, a holistic, end-to-end approach becomes mandatory. To solve the problems identified above (integration inefficiency and communication dysfunction), energy companies need a solution that provides Portfolio-level visibility. An integrated platform offering real-time tracking, efficient resource allocation, and enhanced decision making is a step in the right direction.