Innovative technologies are revolutionizing the way facilities are managed, reducing costs while mitigating risks. Among these advancements, Three-Dimensional Risk Management (3DRM) stands out; it enables the creation of precise models of industrial facilities, offering a digital twin of the physical environment for engineers and project managers to enhance planning, design, and safety assessments.

This transformative technology has found applications across heavy industries, such as mining, construction, manufacturing, and energy, where it optimizes resource allocation, improves asset management, and ensures regulatory compliance.

Activera Consulting, in conjunction with our ecosystem partner Hybird, took a deeper look at how this technology is positively affecting heavy industry. We’ll cover what 3DRM is, what equipment it employs, why a heavy industry player may be interested, and typical associated timeline.

The What

3DRM enables the creation of precise, as-built models that serve as a digital twin of a physical environment. In heavy industries, complex projects often require meticulous planning and design, so 3DRM can be used for the simulation and visualization of project components, workflows, and safety measures before physical construction begins.

In mining and construction, 3DRM can be used to create digital terrain models (DTMs) for site analysis and planning. These models help identify optimal excavation, grading, and foundation designs, minimizing earthworks and reducing costs.

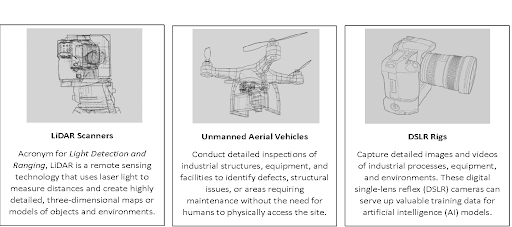

The following equipment is used to enable digital twinning:

The Why

- Enhanced Safety Compliance: Implementing 3D Risk Management (3DRM) in heavy industry operations allows businesses to mitigate safety risks by conducting comprehensive hazard assessments, facilitating incident simulations, and ensuring adherence to industry-specific safety standards.

- Efficient Resource Allocation: 3DRM optimizes resource allocation through advanced predictive analytics, enabling heavy industry businesses to streamline production processes, reduce downtime, and allocate manpower and equipment more effectively, resulting in cost savings and improved operational efficiency.

- Accurate Asset Management: Heavy industry can benefit from 3DRM’s precise asset tracking and monitoring capabilities, optimizing maintenance schedules, extending equipment lifecycles, and minimizing unplanned downtime, ultimately improving asset utilization and ROI.

- Regulatory Compliance Assurance: 3DRM assists heavy industry by ensuring compliance with stringent environmental and regulatory requirements, providing real-time monitoring and reporting tools that track emissions, waste management, and other critical compliance factors which can avoid penalties and reputational risks.

The When

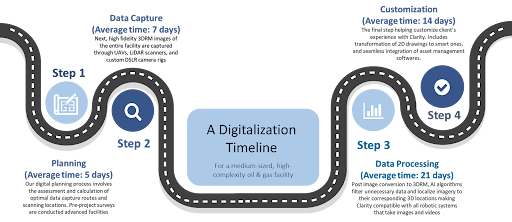

Utilizing the 3DR model, an organization can efficiently manage the entire Planning to Execution stage within a 47-day lifecycle; this encompasses planning, data capture, data processing, and the crucial phase of customization.

3DRM has changed the way heavy industrial facilities operate; reducing errors, producing high quality images, and supplanting tasks that no longer require human intervention. Leveraging cutting-edge tools like LiDAR scanners, drones, and DSLR rigs, we stand on the brink of a paradigm shift that encompasses asset inspection and monitoring, safety management, infrastructure planning and design, and security surveillance. Embracing these advancements paves the way for a future of unparalleled efficiency and innovation in industrial operations.